Sub-Assembly Services

Sub-assembly is the process of combining smaller component pieces to form an entirely new unit before being incorporated into the primary manufacturing process. At Specialty Printing & Processing, we combine our extensive expertise in the specialty printing business with our sub-assembly production to save clients valuable time and money.

What Is Sub-Assembly?

Sub-assembly manufacturing is a process typically done in a separate location or facility that involves pre-building smaller essential components of a larger product before those components hit the assembly line. A typical sub-assembly process follows these steps:

Sub-assembly manufacturing is a process typically done in a separate location or facility that involves pre-building smaller essential components of a larger product before those components hit the assembly line. A typical sub-assembly process follows these steps:

- Individual pieces are provided by the customer or strategically sourced by Specialty Printing and Processing.

- Those pieces are assembled into a new unit away from the line-side

- Completed assemblies/sub-assemblies are delivered to the line-side for final manufacturing

There are many advantages of sub-assembly. Sub-assembly production moves the assembly process further up the supply chain, creating a streamlined process that removes extra steps from the main production line. Sub-assembly reduces lead times while alleviating logistical hurdles.

Sub-assembly manufacturing provides a clear division of tasks, making it easy to pinpoint and troubleshoot supply chain problems as they arise. Specialty Printing & Processing can also source critical parts by ordering the exact part rather than sourcing large, multi-part purchase orders. As an ISO-certified company, we allow clients to maintain ISO compliance by obtaining their subassemblies from us rather than from sources which may not be ISO compliant.

Many of Specialty Printing & Processing’s other services easily combine with sub-assembly manufacturing. Those processes include:

- Printing services

- Die cutting

- Kitting

- Laminating

- Fabricating

- Detailed powder coating

- Marking

- Laser cutting

- Strategic sourcing of components

- Custom packaging, ready to be incorporated with final product

Sub-Assembly Services at Specialty Printing & Processing

Combining other services alongside the sub-assembly process saves our customers time and money, adding value to their overall experience. It streamlines their final assembly process by only providing a single SKU rather than multiple parts, SKUs, and purchase orders. Together, our combined services supply our customers with turnkey solutions.

Printing

Specialty Printing & Processing offers both digital and screen printing services. Using the latest in UV, LED, and solvent printing techniques, we are able to print on almost any material, including metals and plastics, with very few limitations. We specialize in printing on stainless steel products, and can print directly to finished sub-assemblies themselves, saving the customer time and money during the manufacturing process.

With screen printing, our graphics team can develop custom stenciling to apply to your material or product. Digital printing uses computer-rendered images to print labels or directly to your product.

Part of our printing services include custom nameplates and plastic or polycarbonate graphic overlays. Nameplates display company logos and other pertinent branding while overlays often serve as an interface between the finished product and the end user. We can also provide custom labels and decals that bear additional information such as product warnings or instructions. We specialize in large industrial labels for finished products ranging from electronics interfaces to branding for cranes.

Kitting

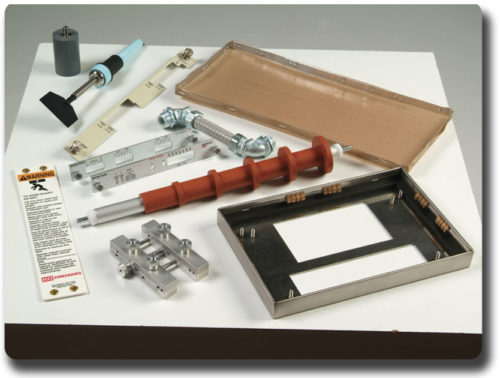

Our kitting service bundles applicable labels, overlays, decals, and nameplates along with any additional hardware necessary to install them onto a sub-assembly or finished product. Our kitting can also include components required with the final shipment, including labels, calibration equipment, locking devices, or safety brackets.

Our kitting service bundles applicable labels, overlays, decals, and nameplates along with any additional hardware necessary to install them onto a sub-assembly or finished product. Our kitting can also include components required with the final shipment, including labels, calibration equipment, locking devices, or safety brackets.

Strategic Sourcing

Specialty Printing & Processing employs a strategic sourcing process that allows us to eliminate logistical hurdles by identifying and sourcing individual pieces used in sub-assembly manufacturing. This process makes it easier to maintain for clients to maintain ISO compliance by sourcing their sub-assemblies through a ISO-certified company like Specialty Printing & Processing.

Mechanical/ Electromechanical Assembly

We are equipped to handle even the toughest custom jobs, including electronic sub-assembly manufacturing. We are able to perform cable and custom electrical assemblies as well.

Other Services

We provide a variety of other services, including but not limited to:

- Plastic assembly (mechanical)

- Solvent welding/gluing

- Adhesive analysis

- Diecutting- including diecutting of metal that’s used in shielding

- Soldering ground leads or connectors

Optimizing Your Sub-Assembly Process

By combining our specialized printing services with sub-assembly manufacturing, Specialty Printing & Processing streamlines the final assembly process, cuts down on manufacturing times, and saves money for our clients. We offer a wide range of services that provide customers with turnkey operations. For more information about how we help with your sub-assembly needs, contact us or request a quote today.