Creative Project Solutions

No matter how complex or unusual a particular challenge, Specialty Printing & Processing will find a solution to fit the exact needs of the application. Our expert team is trained to think outside of the box, and we pride ourselves on continuous process improvement and innovation in everything we do.

Our award-winning staff members have over 100 years of combined experience providing creative, turnkey solutions for clients with all manner of needs. Whether your project is simple or complex, we will draw on our expansive capabilities to print your order exactly as you envision it, along with offering value-added services like design, assembly, testing, and more.

Turnkey Solutions from Specialty Printing & Processing

Specialty Printing & Processing emphasizes turnkey, one-stop solutions for printing projects of all types. At the core of our offerings are our advanced capabilities in both digital printing and screen printing. Our facility is fully stocked with state-of-the-art equipment that allows us to complete complex, high-resolution print jobs on a variety of media. From there, we perform any secondary services necessary, ranging from die-cutting to assembly and delivery. Our goal is to take your project from start to finish as efficiently as possible without sacrificing quality.

Digital Printing

Our professional digital printers routinely achieve a presentation-ready 1,200 dots-per-inch (DPI) resolution, occasionally reaching 2,880 DPI when a particular project demands it. The key to our advanced digital printing abilities lies in a combination of cutting-edge equipment and expert staff. Our professional graphics team has access to in-house Mimaki, Epson, Gerber, and HP systems, allowing them to select the ideal system for each project’s individual constraints. Our facility also houses a full range of roll presses, flatbed digital presses, and inks, allowing us to print on virtually any surface. Specialty inks and coatings are also available.

Our professional digital printers routinely achieve a presentation-ready 1,200 dots-per-inch (DPI) resolution, occasionally reaching 2,880 DPI when a particular project demands it. The key to our advanced digital printing abilities lies in a combination of cutting-edge equipment and expert staff. Our professional graphics team has access to in-house Mimaki, Epson, Gerber, and HP systems, allowing them to select the ideal system for each project’s individual constraints. Our facility also houses a full range of roll presses, flatbed digital presses, and inks, allowing us to print on virtually any surface. Specialty inks and coatings are also available.

Our digital printing services are available on a wide variety of substrates and on surfaces up to 5 feet by 150 feet and can contract printing for up to 14 feet in width. We can also work with you to develop wider images using a paneling solution. With printing speeds of up to 450-square-feet-per-hour, we complete even your largest orders with quick turnarounds.

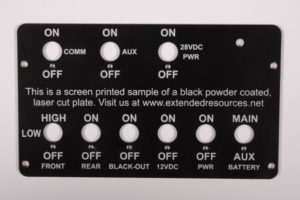

Screen Printing

Our screen printing capabilities are no less extensive. We carry a variety of M&R, American Cameo, and manual presses along with solvent, epoxy, water-based, enamel, and UV type inks. As a result, we can work with all different materials, sizes, and finishes, as well as accommodate advanced printing needs. We print at industry-standard sizes up to 48 x 96 inches, but we also develop innovative screens and fixtures to facilitate non-conventional jobs. No matter the shape or finish of your existing product, we can likely find a way to print on it.

Our screen printing capabilities are no less extensive. We carry a variety of M&R, American Cameo, and manual presses along with solvent, epoxy, water-based, enamel, and UV type inks. As a result, we can work with all different materials, sizes, and finishes, as well as accommodate advanced printing needs. We print at industry-standard sizes up to 48 x 96 inches, but we also develop innovative screens and fixtures to facilitate non-conventional jobs. No matter the shape or finish of your existing product, we can likely find a way to print on it.

We finish our screen printing jobs with the help of a 1 million-BTU belt drying system, as well as smaller and more specialized drying systems, including UV curing and a batch oven system. This ensures an even and professional finish on a broad range of products.

Assembly and Fabrication Services

As a turnkey provider, we offer a range of assembly processes to maximize efficiency. Past projects have called for services ranging from housing manufacture to electromechanical assembly, and our engineered processes solved the challenge. In addition, we can combine assembly, printing, and fabrication services, allowing customers more flexibility in the production process. Our capabilities include the design and production of assemblies for complex, multi-part components, and we offer plastic, electrical, and mechanical assembly to meet a broader range of customer requirements.

As a turnkey provider, we offer a range of assembly processes to maximize efficiency. Past projects have called for services ranging from housing manufacture to electromechanical assembly, and our engineered processes solved the challenge. In addition, we can combine assembly, printing, and fabrication services, allowing customers more flexibility in the production process. Our capabilities include the design and production of assemblies for complex, multi-part components, and we offer plastic, electrical, and mechanical assembly to meet a broader range of customer requirements.

Our fabrication services include lamination, die-cutting, packaging, kitting, and more. Our responsive sales team would be happy to discuss specific needs, including our full range of assembly and fabrication services.

Additional Services Offered

Specialty Printing & Processing is committed to supporting our clients at every step of the process. As such, our services extend beyond standard printing and assembly to include a wider range of useful offerings, such as:

- Design services. If you partner with Specialty Printing & Processing in the early stages of development, we can assist with design services for the printed graphic as well as the physical assembly. Our design expertise underlies our ability to tackle more challenging printing projects.

- Complex part printing. It’s sometimes necessary to print directly on an abnormally shaped product. In these instances, we design custom components to work with our existing presses, allowing us to seamlessly print on complex parts.

- Adhesive analysis. To maximize the longevity of our overlays and labels, we can perform a comprehensive adhesive analysis to select the best material for your product.

- Die-cutting. Our staff are skilled in high-precision die-cutting for labels and other products that must be trimmed to a specific size and shape. We work with both standard and custom dies to achieve custom shapes for high-volume runs, as well as route features like tabs or cutouts.

With our solutions-focused approach, Specialty Printing can undertake a wider variety of jobs than a standard printer. Request a consultation for more information about our capabilities.

Products

Our combination of expertise and advanced equipment lends itself to a diverse set of products, all of which are customizable to your specifications.

Polycarbonate Overlays

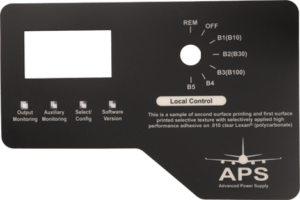

Polycarbonate (Lexan) overlays sit atop moldings, assemblies, and panels to provide necessary labeling or aesthetic detailing. We offer standard prints with die-cut details, and we can also meet special design requirements such as texturing or backlighting.

Nameplates

One of our specialties is custom nameplate production, including both low- and high-volume production runs of products such as nameplates, data plates, and similar informational plates. Our custom prints are available with custom aesthetic features, including texturing and custom colors, to make your plates functional as well as attractive.

Custom Labels

We proudly serve as a one-stop-shop for custom labels and decals of all shapes and sizes. Our team will work closely with you to determine the ideal material, size, and adhesive for a long-lasting seal.

Specialty Signage

Our custom signs can be printed on metal, plastic, synthetics, wood, or even flexible films and are adorned with high-resolution prints. As with our other products, we are able to accommodate various thicknesses, sizes, and shapes, but we also offer secondary services unique to our signage customers. These offerings include custom mounting, hanging, and display preparations, among others.

Custom Digital Graphics

We also offer simple, high-resolution digital printing services for small or large-format products. Whether your end result is a banner, insert, product ID, or nameplate, we’ll select the ideal materials to execute a professional and durable printed result.

Assembled Projects

As our array of secondary services might suggest, we are well-equipped to cut, coat, and assemble products before delivery. Drawing on our ability to manufacture custom screens, we can also print directly onto products that have been molded, powder-coated, or assembled prior to reaching us.

Turn-Key Projects

At Specialty Printing & Processing, our goal is to provide a true turnkey solution for customers from a diverse range of industries. Whether an order calls for small, standard screen prints or a large, custom decal, we have the equipment and the experience to satisfy those requirements at a competitive price point. From design to assembly, packaging, and delivery, Specialty Printing & Processing is here to provide professional guidance and skilled execution.

Working with Specialty Printing and Processing

As a turnkey provider specializing in creative solutions to challenging printing problems, we follow a simple system that allows us to identify and meet our customer’s needs. When you work with Specialty Printing & Processing, you can expect to work through the following stages with us:

Identifying a Problem

When a client first comes to us with a question or quote request, we work to identify the core problem or design challenge that we must solve. This might be achieving a flawless digital print on a pre-formed plastic component, for instance, or putting together a particularly complex electromechanical assembly. Regardless of the specifics, the first step is always to pinpoint our customer’s specifications and requirements, which guide the remainder of our working relationship.

Working With a Team of Experts

Combined, our staff has over 100 years of printing and manufacturing experience. Once we’ve identified a problem, we leverage our expertise, supplier contacts, and innovative design capabilities to identify the materials and processes that will best address the challenge.

Creative Solutions

By the end of our design process, we’ll come to you with the results of our research and brainstorming. No matter how complex the original design challenge, we pride ourselves on finding solutions that other companies can’t. Whether you have a high-heat product and need an adhesive or you want us to print directly onto stainless steel, we’ll make it happen.

Request Your Creative Solution Today

Specialty Printing & Processing has the tools, team, and capabilities necessary to tackle the toughest design challenges. To learn more about our turnkey solutions or to request information about how we can meet your particular needs, contact us or request a consultation today.